The concrete buggy has come a long way since its humble beginnings as a simple wheelbarrow. In the early days of construction, workers would manually mix and transport concrete using wheelbarrows, which was not only labor-intensive but also time-consuming. As construction projects grew in scale and complexity, the need for a more efficient and reliable method of transporting concrete became apparent. This led to the development of the first concrete buggy, which was essentially a motorized wheelbarrow that could carry larger loads of concrete over rough terrain.

Over time, the design and functionality of concrete buggies continued to evolve, with manufacturers incorporating features such as hydraulic dumping mechanisms, self-propelled engines, and increased load capacities. These advancements not only improved the efficiency and productivity of construction projects but also reduced the physical strain on workers. Today, modern concrete buggies are equipped with state-of-the-art technology and ergonomic design elements that make them indispensable tools on construction sites. From remote-controlled operation to all-terrain capabilities, the evolution of the concrete buggy has revolutionized the way concrete is transported and placed, making construction processes faster, safer, and more cost-effective.

The evolution of the concrete buggy from a simple wheelbarrow to a sophisticated piece of machinery is a testament to the ingenuity and innovation of the construction industry. As construction methods continue to advance, it is likely that we will see further improvements in concrete buggy design and functionality, ultimately leading to even greater efficiency and productivity on construction sites.

Key Takeaways

- Concrete buggies have evolved from wheelbarrows to modern machines, increasing efficiency and productivity on construction sites.

- Using a concrete buggy on construction sites offers advantages such as increased productivity, reduced labor costs, and improved safety.

- There are two main types of concrete buggies: wheeled and tracked, each with their own advantages and disadvantages.

- When choosing the right concrete buggy for your project, consider factors such as the type of terrain, capacity, and maneuverability required.

- Safety considerations when operating a concrete buggy include proper training, wearing personal protective equipment, and following manufacturer guidelines.

- To keep your concrete buggy in top condition, regular maintenance such as cleaning, lubrication, and inspection is essential.

- Modern concrete buggies feature innovative technologies such as remote control operation, GPS tracking, and advanced safety features for improved efficiency and safety on construction sites.

Advantages of Using a Concrete Buggy on Construction Sites

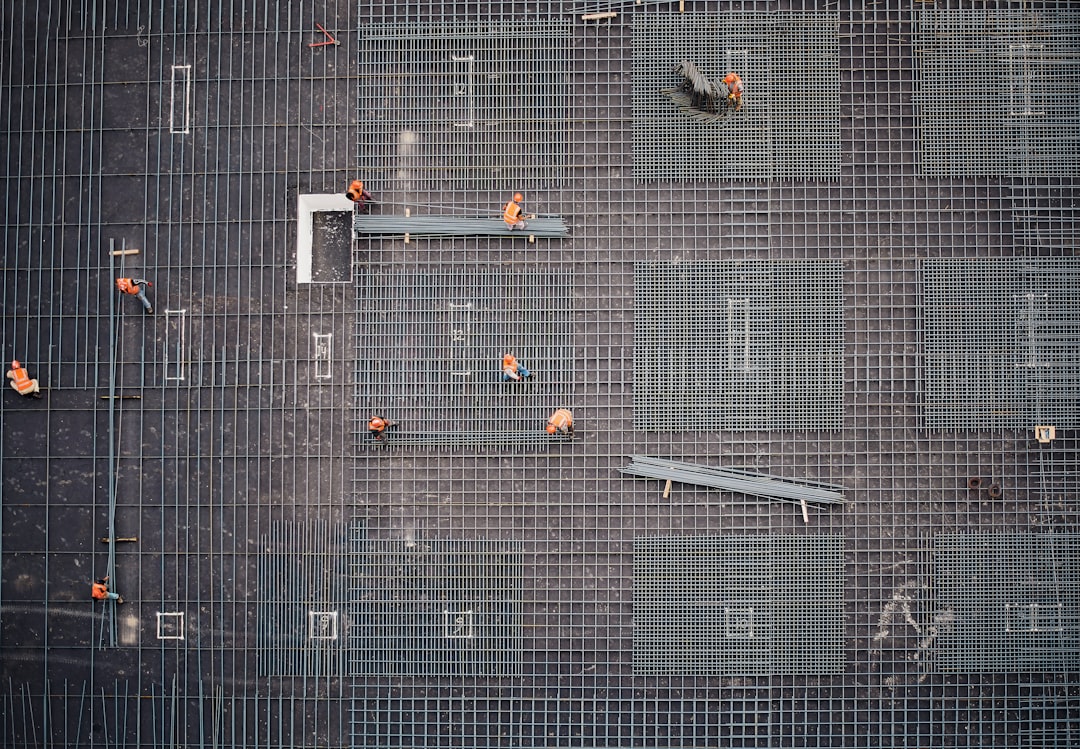

The use of a concrete buggy on construction sites offers numerous advantages that contribute to increased efficiency, productivity, and safety. One of the primary benefits of using a concrete buggy is its ability to transport large volumes of concrete quickly and easily, reducing the need for manual labor and minimizing the risk of injury. This is especially important on large-scale construction projects where time is of the essence and deadlines must be met.

Additionally, concrete buggies are designed to navigate rough terrain and tight spaces with ease, making them ideal for use in a variety of construction environments. Their all-terrain capabilities allow for seamless transportation of concrete across uneven surfaces, reducing the risk of spills and ensuring that concrete can be delivered precisely where it is needed. Furthermore, modern concrete buggies are equipped with features such as hydraulic dumping mechanisms and adjustable chutes, allowing for precise placement of concrete without the need for additional equipment or manual labor.

Another advantage of using a concrete buggy is its ability to improve overall project efficiency by reducing downtime and increasing productivity. With the ability to transport and place concrete quickly and accurately, construction crews can complete tasks more efficiently, ultimately saving time and money. In addition, the use of a concrete buggy can help minimize waste by ensuring that concrete is delivered and placed exactly where it is needed, reducing the likelihood of over-pouring or spillage.

Types of Concrete Buggies: Wheeled vs. Tracked

When it comes to choosing a concrete buggy for your construction project, one of the key decisions you will need to make is whether to opt for a wheeled or tracked model. Both types of concrete buggies offer distinct advantages and are suited to different types of construction environments.

Wheeled concrete buggies are ideal for use on flat or moderately uneven surfaces, such as indoor construction sites or paved areas. They are designed to maneuver easily and can travel at higher speeds, making them well-suited for projects that require frequent transportation of concrete over short distances. Wheeled concrete buggies are also typically more affordable than their tracked counterparts, making them a cost-effective option for smaller-scale projects.

On the other hand, tracked concrete buggies are designed to navigate rough terrain and steep inclines with ease, making them ideal for use in outdoor construction environments or on projects that require transportation over challenging surfaces. Their superior traction and stability make them well-suited for use on uneven or soft ground, ensuring that concrete can be delivered precisely where it is needed without the risk of slippage or loss of control. While tracked concrete buggies may be more expensive than wheeled models, their all-terrain capabilities make them an invaluable tool for projects that require reliable transportation over challenging terrain.

Ultimately, the choice between wheeled and tracked concrete buggies will depend on the specific requirements of your construction project, including the type of terrain you will be working on and the distance over which concrete will need to be transported. By carefully considering these factors, you can select the type of concrete buggy that best meets your project needs.

How to Choose the Right Concrete Buggy for Your Project

| Concrete Buggy Model | Weight Capacity | Engine Power | Bucket Size | Turning Radius |

|---|---|---|---|---|

| Model A | 2500 lbs | 20 hp | 16 cu ft | 8 ft |

| Model B | 3000 lbs | 25 hp | 18 cu ft | 9 ft |

| Model C | 3500 lbs | 30 hp | 20 cu ft | 10 ft |

Choosing the right concrete buggy for your project is essential to ensuring that you have the equipment necessary to complete tasks efficiently and safely. When selecting a concrete buggy, there are several key factors to consider that will help you make an informed decision.

First and foremost, it is important to consider the capacity and load-bearing capabilities of the concrete buggy. The size and volume of concrete loads that will need to be transported on your project will dictate the capacity requirements of the buggy. Additionally, it is important to consider factors such as maneuverability and ease of operation, as these will impact the efficiency and productivity of your construction crew.

Another important consideration when choosing a concrete buggy is the type of terrain on which it will be used. If your project involves navigating rough or uneven surfaces, a tracked concrete buggy may be the best option due to its superior traction and stability. Conversely, if your project involves primarily flat or paved surfaces, a wheeled concrete buggy may be more suitable.

It is also important to consider any additional features or accessories that may be necessary for your project. For example, if your project requires precise placement of concrete in hard-to-reach areas, you may want to consider a concrete buggy with an adjustable chute or remote-controlled operation.

By carefully considering these factors and conducting thorough research into the available options, you can choose a concrete buggy that meets the specific requirements of your project, ultimately contributing to increased efficiency, productivity, and safety on your construction site.

Safety Considerations When Operating a Concrete Buggy

While concrete buggies are invaluable tools for transporting and placing concrete on construction sites, it is essential to prioritize safety when operating these machines. Due to their size and power, concrete buggies can pose significant risks if not operated correctly. Therefore, it is important for construction crews to adhere to strict safety protocols when using these machines.

One of the primary safety considerations when operating a concrete buggy is ensuring that all operators are properly trained and certified to use the equipment. This includes familiarizing operators with the specific features and controls of the concrete buggy, as well as providing comprehensive training on safe operating practices. Additionally, operators should be aware of potential hazards associated with operating a concrete buggy, such as tipping or rollover incidents, and should be trained in how to mitigate these risks.

It is also important to conduct regular inspections and maintenance checks on concrete buggies to ensure that they are in safe working condition. This includes checking for any signs of wear or damage, as well as ensuring that all safety features are functioning properly. By conducting routine maintenance checks, construction crews can identify and address any potential safety concerns before they escalate into more serious issues.

Furthermore, it is essential for operators to adhere to strict guidelines regarding load capacities and weight distribution when using a concrete buggy. Overloading a concrete buggy can lead to instability and loss of control, posing significant risks to both operators and bystanders. By following recommended load capacities and weight distribution guidelines, operators can minimize the risk of accidents and ensure safe operation of the equipment.

By prioritizing safety considerations when operating a concrete buggy, construction crews can minimize risks and create a safer working environment for all personnel on the construction site.

Maintenance Tips for Keeping Your Concrete Buggy in Top Condition

Proper maintenance is essential for keeping your concrete buggy in top condition and ensuring its long-term reliability and performance. By following a regular maintenance schedule and conducting routine checks, you can identify and address any potential issues before they escalate into more serious problems.

One important aspect of maintaining a concrete buggy is conducting regular inspections to check for signs of wear or damage. This includes inspecting key components such as tires, hydraulics, engine components, and structural elements for any signs of wear or deterioration. By identifying potential issues early on, you can address them before they lead to more significant problems that could impact the performance or safety of the equipment.

In addition to regular inspections, it is important to adhere to recommended maintenance schedules for key components such as engine oil changes, filter replacements, and hydraulic system checks. By following manufacturer guidelines for maintenance intervals and procedures, you can ensure that your concrete buggy remains in optimal working condition.

Furthermore, it is important to keep your concrete buggy clean and free from debris or buildup that could impact its performance. This includes regularly cleaning components such as the chassis, engine compartment, and hydraulic systems to prevent dirt or debris from causing damage or malfunctions.

Finally, it is essential to store your concrete buggy in a clean, dry environment when not in use to prevent corrosion or deterioration. By following proper storage practices, you can extend the lifespan of your equipment and ensure that it remains in top condition for years to come.

By following these maintenance tips and conducting routine checks on your concrete buggy, you can ensure that it remains in optimal working condition, ultimately contributing to increased efficiency and productivity on your construction site.

Innovative Features and Technologies in Modern Concrete Buggies

Modern concrete buggies are equipped with innovative features and technologies that have revolutionized the way construction crews transport and place concrete on job sites. From advanced control systems to ergonomic design elements, these innovative features contribute to increased efficiency, productivity, and safety in construction operations.

One notable innovation in modern concrete buggies is the integration of advanced control systems that allow for precise operation and placement of concrete. Remote-controlled operation systems enable operators to maneuver the buggy with precision, allowing for accurate placement of concrete in hard-to-reach areas without the need for manual labor or additional equipment. This not only improves efficiency but also reduces physical strain on operators by minimizing the need for manual labor.

Additionally, modern concrete buggies are equipped with ergonomic design elements that prioritize operator comfort and safety. Features such as adjustable operator seats, intuitive control interfaces, and enhanced visibility contribute to a more comfortable and user-friendly operating experience. By prioritizing operator comfort and safety, modern concrete buggies help minimize operator fatigue and reduce the risk of accidents or injuries on construction sites.

Furthermore, advancements in technology have led to improvements in areas such as fuel efficiency, emissions control, and noise reduction in modern concrete buggies. These advancements not only contribute to reduced environmental impact but also result in cost savings for construction companies by minimizing fuel consumption and maintenance requirements.

Overall, innovative features and technologies in modern concrete buggies have transformed the way construction crews transport and place concrete on job sites. By prioritizing precision operation, operator comfort, and environmental sustainability, these advancements contribute to increased efficiency, productivity, and safety in construction operations.

Innovative features such as remote control operation, advanced hydraulic systems, and ergonomic design have revolutionized the concrete buggy industry. These advancements allow for more precise placement of concrete, reducing waste and improving overall project quality. Additionally, the integration of electric and hybrid power options in modern concrete buggies not only reduces emissions and noise pollution but also lowers operating costs for construction companies. As a result, construction crews can work more efficiently and safely, ultimately leading to improved project timelines and client satisfaction.

If you’re interested in learning more about concrete buggies, check out this article on goalscopes.com that provides a comprehensive guide to choosing the right concrete buggy for your construction project. This article covers important factors to consider such as weight capacity, maneuverability, and power source, helping you make an informed decision when selecting a concrete buggy for your specific needs.

FAQs

What is a concrete buggy?

A concrete buggy, also known as a power buggy, is a motorized vehicle used to transport and pour concrete on construction sites. It is designed to easily maneuver through tight spaces and rough terrain, making it ideal for transporting concrete to hard-to-reach areas.

How does a concrete buggy work?

A concrete buggy is powered by a gasoline or electric engine and is equipped with a large bucket or hopper to hold the concrete. The operator controls the buggy’s movement and the pouring of the concrete using a set of handles and controls.

What are the benefits of using a concrete buggy?

Using a concrete buggy can significantly increase efficiency and productivity on a construction site. It allows for quick and easy transportation of concrete, reducing the need for manual labor and minimizing the risk of injuries associated with heavy lifting.

What are the different types of concrete buggies?

There are various types of concrete buggies available, including walk-behind and ride-on models. Walk-behind buggies are typically used for smaller jobs and can be maneuvered manually, while ride-on buggies are larger and can carry a greater volume of concrete.

What are the safety considerations when using a concrete buggy?

Operators of concrete buggies should be properly trained and follow all safety guidelines provided by the manufacturer. It is important to wear appropriate personal protective equipment, such as gloves and safety goggles, and to be aware of the surrounding environment to avoid accidents.